ABOUT US

Founded in 1981, Matchling Tooling Co., Ltd. specializes in the research and manufacturing of high-precision machine tool components. We are committed to providing advanced and reliable solutions for the global industrial sector. With products sold in over 60 countries, more than 20 international patents, and participation in over 800 international trade shows, we demonstrate strong R&D capabilities and global competitiveness.We offer a comprehensive portfolio of over 9,000 machine tool accessory products, including high-precision components for CNC machining centers, lathes, grinders, and milling machines, as well as vises and other clamping tools. Our one-stop service makes us one of the largest and most systematized precision machinery component suppliers in Taiwan.Upholding the principle of “Quality First, Customer Foremost,” MATCHLING continuously integrates automation and cutting-edge global technologies to optimize production processes and quality management. We strive to enhance product efficiency, accuracy, and competitiveness—aiming to be your most trusted partner in precision engineering. .embed-container { position:relative; padding-bottom: 56.25%; height: 0; overflow: hidden; max-width: 100%;} .embed-container iframe, .embed-container object, .embed-container embed {position: absolute; top: 0; left: 0; width: 100%; height: 100%; }

HOT PRODUCTS

Hot Products

21256 Zero Point System

A Zero Point System is a high-precision and quick-change solution for fixture positioning and clamping. By using a “zero point” as a reference, workpieces or fixtures can be mounted and removed from the machine tool quickly and accurately, significantly reducing setup time and increasing machining efficiency.Why Choose a Zero Point System?By adopting a Zero Point Clamping System, manufacturers can reduce setup time, improve machining accuracy, and optimize workflow, helping businesses stay competitive in the manufacturing industry.Advantages of Zero Point SystemQuick Changeover: Reduces setup and positioning time, boosting productivity.High Precision Positioning: Ensures repeat positioning accuracy within 0.005mm, guaranteeing machining quality.Increased Machine Utilization: Minimizes machine downtime and maximizes output.Modular Application: Compatible with different fixtures, suitable for CNC machines, inspection, and automation lines.

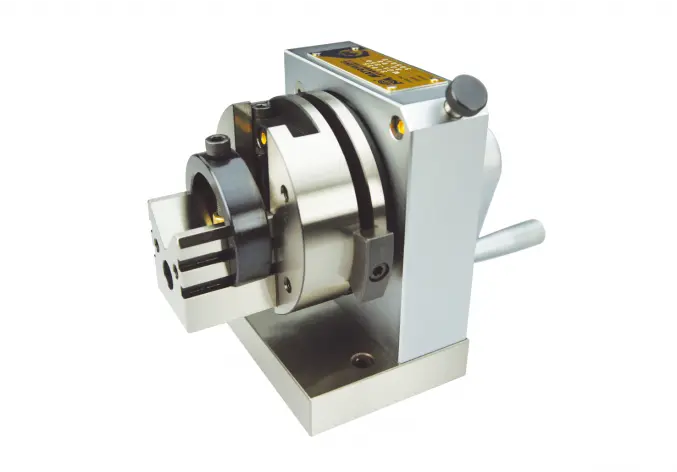

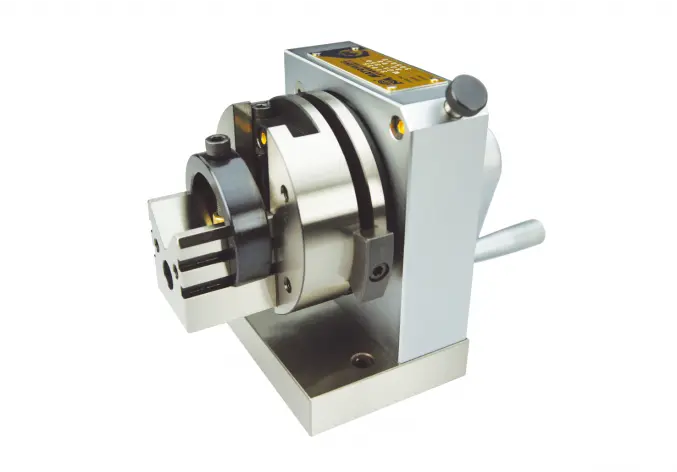

31035 PUNCH FORMER

The Punch Grinder (V-type Clamping Model) is a precision grinding machine designed for punches, mold components, and small cylindrical workpieces.With its V-block clamping structure, it firmly secures workpieces at the center, preventing displacement and vibration to achieve higher accuracy and efficiency.Applications : Widely used in mold manufacturing, precision machining, and hardware production.Punch Grinding – Maintains punch centering, extending mold life.Mold Component Grinding – Ideal for clamping small-diameter and long parts.Cylindrical Workpieces – Ensures concentricity and improves surface finish.Mass Production – Quick clamping/releasing reduces downtime.Key AdvantagesHigh Precision – Keeps workpieces centered for accuracy.Excellent Stability – Prevents wobbling and loosening.Quick Operation – Fast clamping and releasing.Versatility – Works with punches, molds, and cylindrical parts.

35050 Hydraulic Machine Vise

Hydraulic machine vise for CNC and milling machines, featuring automatic pressure clamping, rigid FC30 cast iron body, and precision-ground slideways.

HOT NEWS

Feb 25,2026

2026 ITES

2026.3.31-4.3 Shenzhen World Exhibition & Convention Center

Oct 30,2025

2025 DMP GREATER BAY ARER INOUSTRIAL EXPO

【DMP 2025】The Most Anticipated Machine Tool Event Showcasing China’s Homegrown Innovation Potential!

Jan 08,2025